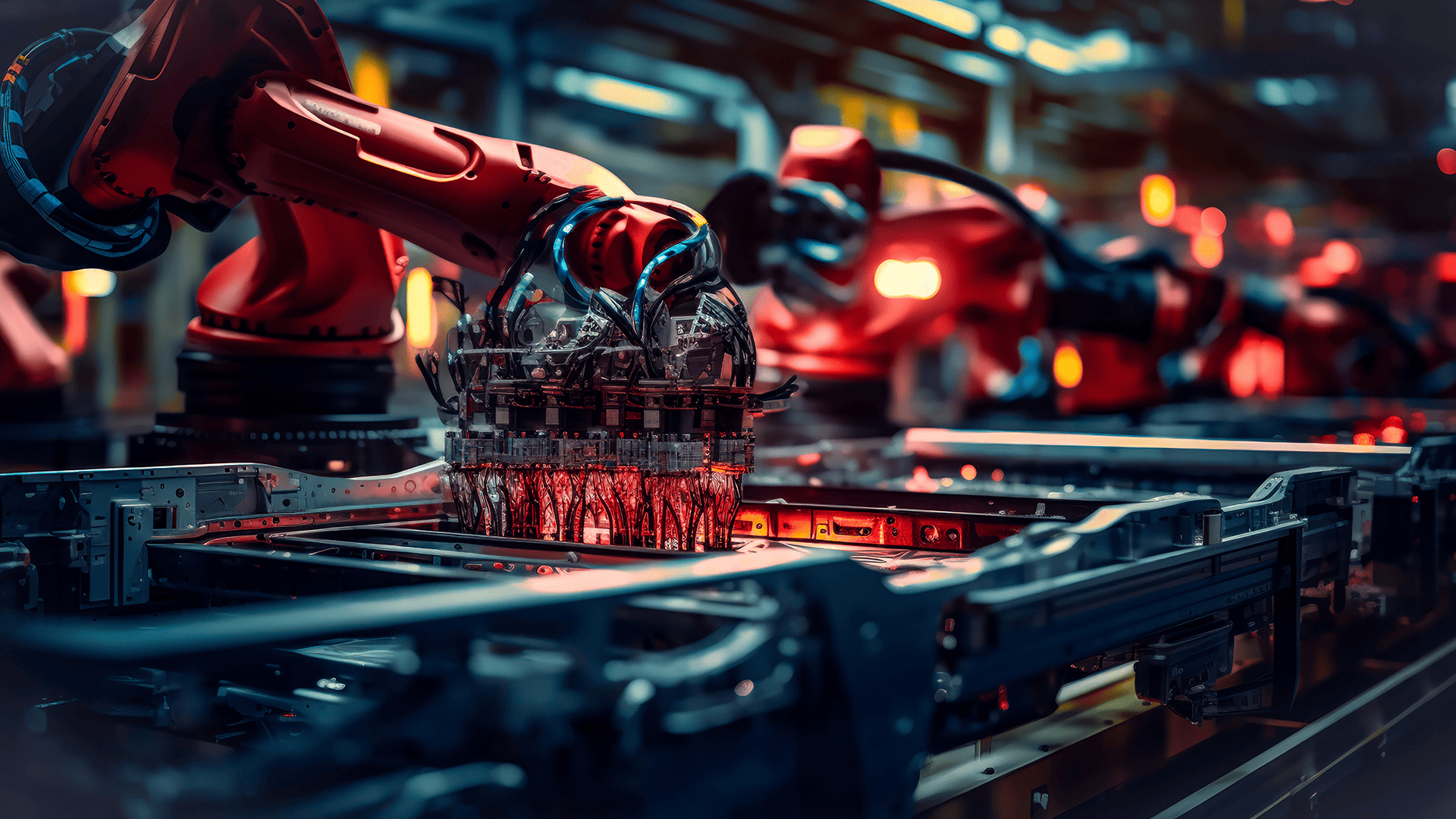

At Progress Machine Ltd., we take pride in our advanced equipment and the high-quality projects we've completed over the years. Our facility is equipped with cutting-edge machinery capable of handling complex and large-scale tasks across multiple industries — from mining and heavy machining to CNC manufacturing and veneer product fabrication.

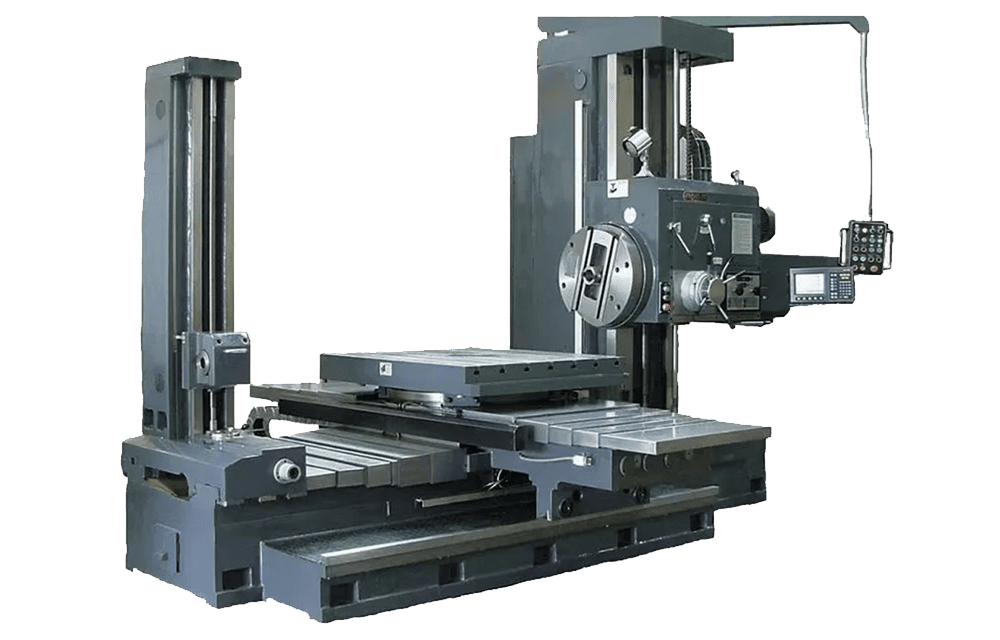

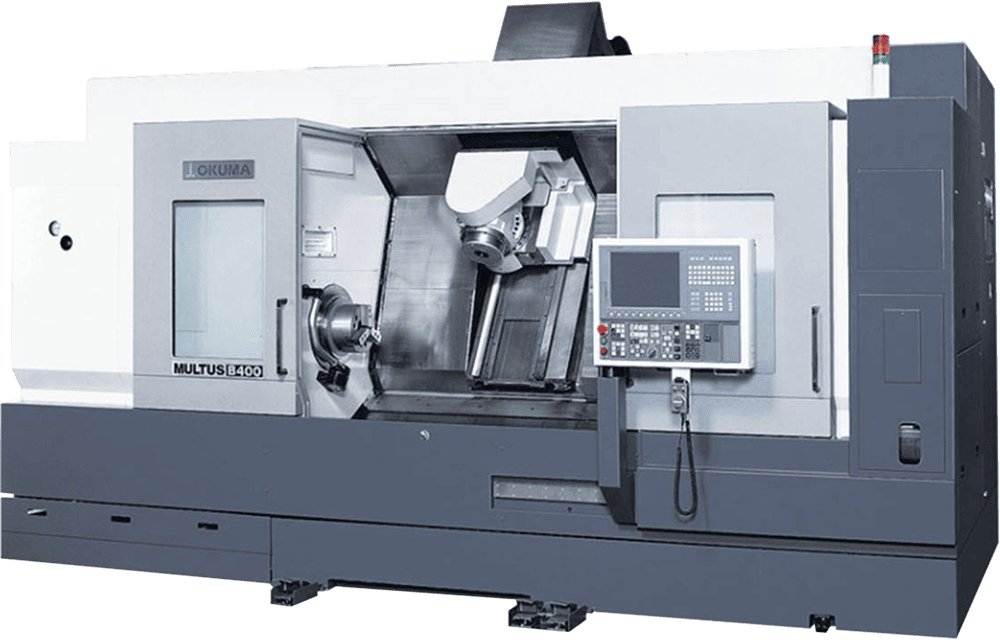

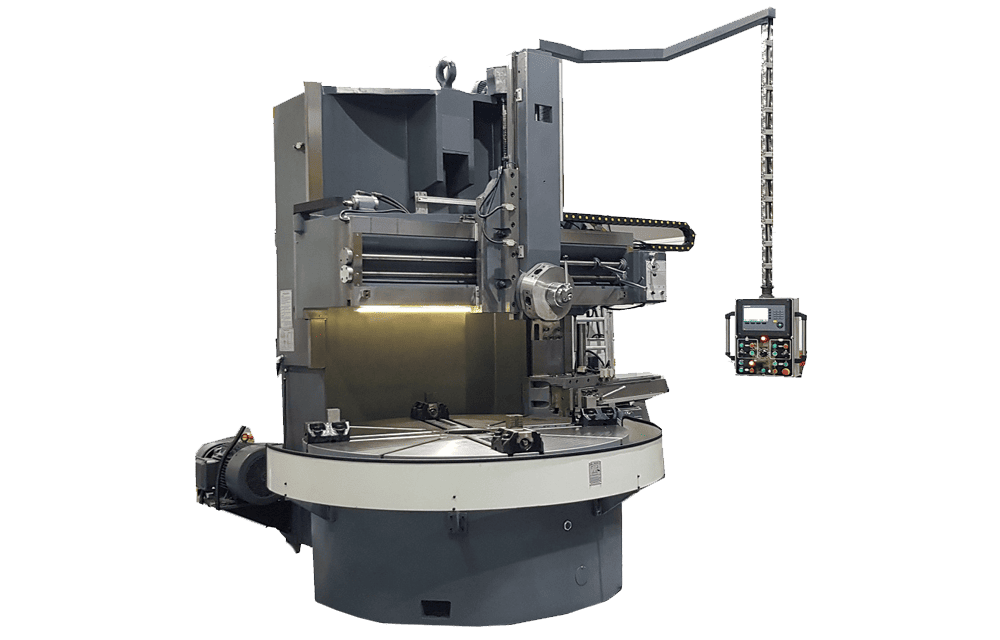

We specialize in repairing and rebuilding cone crusher components, performing high-precision 5-axis machining, and delivering custom metalwork solutions using our Okuma B400W CNC machine, vertical lathe (up to 16 tons and 100 inches in diameter), and horizontal boring mill. These powerful machines allow us to maintain tight tolerances and ensure unmatched durability and performance.

Over the years, we’ve successfully completed a wide range of projects for clients across Canada and beyond. Each project reflects our commitment to precision, reliability, and client satisfaction. Whether it’s restoring critical equipment for the mining industry or fabricating detailed components from scratch, our team delivers with excellence.

Explore this page to see the machines that power our work and real examples of how we’ve used them to bring value to our customers.